E-commerce companies face two major inventory challenges: lost sales from stockouts and wasted funds on excess inventory. AI is transforming inventory management by using tools like machine learning and predictive analytics to solve these issues. Here’s how AI helps:

- Demand Forecasting: Combines historical data with real-time factors like social trends or weather to improve accuracy by up to 30%.

- Automated Replenishment: Dynamically adjusts orders based on real-time data, reducing stockouts by 65%.

- Real-Time Visibility: Tracks inventory instantly using sensors and updates systems to minimize errors and delays.

- Warehouse Optimization: Enhances efficiency by organizing products and routes, cutting picking times and errors.

- Anomaly Detection: Flags discrepancies and slow-moving stock, reducing waste and unlocking cash flow.

AI-driven systems reduce inventory levels by 20–30%, cut costs, and improve accuracy to over 90%. Companies like Danone and Walmart are already seeing results, with improved forecasting, fewer errors, and increased profits. If you’re not using AI for inventory, you’re likely falling behind.

AI Inventory Management: Predict Demand, Prevent Stockouts

sbb-itb-f73ecc6

1. Demand Forecasting and Demand Sensing

AI-driven demand forecasting combines historical sales data with real-time inputs like social media trends, weather changes, competitor pricing, and economic indicators. Unlike older, linear models that depend solely on past sales, AI uses neural networks and deep learning to uncover complex patterns. For example, a viral TikTok trend paired with unexpected weather shifts could lead to a sudden spike in demand. This level of demand sensing leads to better inventory management and cost savings.

The results are impressive. Danone, a major yogurt producer, used AI to manage its perishable goods, cutting forecast errors by 20% and achieving 92% forecast accuracy. Novolex, a packaging company, reduced excess inventory by 16% and shortened its planning cycles from weeks to just days through AI-powered forecasting. Similarly, Asia’s largest spice company partnered with ConverSight to implement the Athena AI assistant, which improved forecasting accuracy by 30% and reduced inventory waste by 20%.

Impact on Inventory Accuracy and Efficiency

AI provides forecasts at the SKU, store, and daily levels, unlike traditional methods that often rely on broader category-level data. This granular approach is essential, especially since inventory accuracy in U.S. retail averages only 63%. AI systems also continuously learn and adapt to new data – whether it’s unexpected shipping delays or viral trends – ensuring forecasts stay accurate in real time. This adaptability reduces errors and enhances overall efficiency.

Cost Reduction and Better Cash Flow

By optimizing inventory, AI prevents companies from tying up cash in unnecessary safety stock. Businesses using AI for forecasting have reported inventory reductions of 20% to 30%, freeing up funds and minimizing last-minute markdowns. Additionally, AI can lower logistics costs by 20% and procurement costs by 15%. It’s no wonder that 25% of companies credit AI-driven demand planning with increasing their Earnings Before Interest and Taxes (EBIT) by more than 5%.

Seamless Integration with Existing Systems

Modern AI forecasting tools are designed to integrate easily with popular platforms like Shopify and BigCommerce, as well as ERP and Order Management Systems such as Brightpearl, Linnworks, and Cin7. These tools enable two-way data exchange, pulling in information and updating reorder parameters directly within planning systems. To get started, ensure you have 12–18 months of clean, structured historical data. Begin with a pilot project targeting a high-impact category instead of overhauling everything at once. Incorporate a "human-in-the-loop" approach, where AI manages steady-demand products while human input is used for new launches or unexpected disruptions.

2. Automated Replenishment and Purchase Order Optimization

After AI’s success in improving demand forecasting, its ability to automate replenishment takes inventory management to the next level.

AI simplifies reordering by using real-time data like sales trends, supplier lead times, seasonal patterns, and disruptions to trigger purchase orders dynamically. This approach replaces outdated "min-max" inventory levels. By shifting from reactive "firefighting" to proactive planning, businesses can avoid emergency orders and costly expedited shipping fees .

For instance, Migros adopted Invent.ai‘s automated replenishment system over five months, achieving an 11% reduction in inventory days, a 1.3% drop in lost sales, and a 1.7% improvement in stock availability. Ilker Tunaboyu, Supply Chain and Marketing Planning Director, highlighted the impact:

"We saw a significant reduction in working capital in just five months. With 1.3% lost sales reduction, inventory days reduced by more than 11% and stock availability increased by 1.7%."

Similarly, Shelf Engine helped a major U.S. grocery chain generate $40 million in additional profit in just one year by using AI to optimize replenishment and minimize waste.

Impact on Inventory Accuracy and Efficiency

AI doesn’t just enhance forecasting – it also uses those insights to refine stock ordering. Routine reordering is handled automatically, allowing human planners to focus on exceptions or anomalies flagged by the system. By incorporating stochastic modeling, AI accounts for uncertainties like supplier delays or sudden demand spikes. This reduces manual intervention and cuts product unavailability by 65% . As a result, service levels can increase by 10% to 20%.

Cost Reduction and Improved Cash Flow

AI’s dynamic safety stock adjustments prevent over-ordering, lowering procurement and logistics expenses. Research from McKinsey shows that AI can reduce inventory levels by 20% to 30% and cut logistics costs by 5% to 20%. These savings free up working capital, which businesses can redirect into areas like marketing or product innovation . On average, mid-to-large companies report a 300% ROI within 18 months of implementing AI-driven inventory solutions. Additionally, AI can reduce stranded inventory by 15% to 30% and waste by 25% to 35%.

Seamless Integration with Existing Systems

AI tools are designed to integrate smoothly with ERP, WMS, and OMS platforms through APIs, enabling real-time data exchange with major U.S. sales channels. These tools can write optimized reorder parameters directly into planning systems . Integration typically takes 4 to 12 weeks. To begin, businesses should audit at least 24 months of historical data to ensure algorithm accuracy. Launching a pilot with high-volume SKUs can demonstrate immediate ROI before scaling. Running "what-if" simulations on historical data is another way to test the AI’s effectiveness before going live .

This level of proactive management not only improves purchase order accuracy but also lays the groundwork for better inventory control and risk management in real time.

3. Real-Time Inventory Visibility and Stock Accuracy

Once AI takes over automated replenishment, the next hurdle is making sure your inventory data matches reality across every warehouse, store, and sales channel. Traditional tracking systems often update stock records with delays ranging from 31 to 59 minutes. This lag is a major issue – 38.6% of retailers report canceling at least 10% of orders due to phantom inventory.

AI solves this problem by creating a centralized data system that pulls real-time information from barcode scanners, RFID tags, IoT shelf sensors, and vision systems. As soon as an item is scanned, AI updates stock levels instantly across ERP, WMS, and OMS platforms. If there’s a mismatch – like a shipment being marked as received but not scanned into inventory within 24 hours – AI flags the error right away. This ensures stock levels are updated in real-time across all sales channels, minimizing errors and delays.

Impact on Inventory Accuracy and Efficiency

Low inventory accuracy has always been a tough challenge for businesses. Real-time tracking, combined with AI-driven forecasting, significantly improves accuracy. For example, CarboNet, a company specializing in advanced chemistry, switched to an AI-supported real-time tracking system in April 2025. The result? They saved countless hours each week that were previously spent on manual inventory checks. Similarly, Danone used AI to track its perishable yogurt products, achieving 92% forecast accuracy and reducing forecast errors by 20%.

Cutting Costs and Boosting Cash Flow

Real-time visibility doesn’t just improve accuracy – it also slashes costs. Inventory often ties up 25%–30% of a product’s value. By eliminating phantom inventory and avoiding overstock, AI can reduce overall inventory levels by 20% to 30%. This optimization frees up working capital, with some companies unlocking up to 30% of tied-up cash in just weeks. That cash can then be reinvested into marketing, product development, or even paying down debt. On top of that, businesses using AI inventory management have reported an ROI as high as 927%. AI also helps cut logistics costs by up to 20% and procurement costs by up to 15%.

Scalability for E-Commerce in the U.S.

AI systems are built to handle the complexity of e-commerce operations, tracking millions of SKUs across global production and fulfillment locations without needing a larger workforce. Whether you’re running a single warehouse in Ohio or managing a nationwide network, AI can scale easily. It uses tools like vision systems and autonomous drones to monitor stock movement and perform visual audits of shelves and aisles. These systems even overcome challenges like RFID signal interference caused by metal or liquids, making them more reliable than traditional methods.

Seamless Integration with Existing Systems

Modern AI-powered OMS platforms act as a central hub, ensuring clean, synchronized data flows into AI models and enabling proactive inventory management. Integration with legacy systems like ERP, WMS, and OMS typically relies on APIs or middleware to break down data silos. Before diving in, it’s smart to audit your data sources and start small – perhaps with a pilot program that automates stock checks in a single high-traffic warehouse. From there, you can expand gradually. By setting up AI-driven notifications for stock mismatches and creating custom dashboards, teams across operations, finance, and warehousing can access the same real-time data. This unified approach not only strengthens your financial position but also lays the groundwork for smarter warehouse and fulfillment strategies.

4. Warehouse and Fulfillment Optimization

Once real-time inventory visibility is established, the next big step is improving how your warehouse operates. AI takes the lead here by streamlining product flow across your facility. It continuously adjusts product placement based on real-time demand trends. For example, high-demand items are stored closer to packing stations, while commonly paired products are placed side-by-side. This setup helps pickers save time and energy, bundling orders faster without unnecessary walking.

Impact on Inventory Accuracy and Efficiency

AI doesn’t just optimize placement; it also calculates the most efficient routes for both human pickers and automated mobile robots (AMRs). This reduces travel time and eliminates bottlenecks. One Logiwa customer, for instance, slashed daily task times by 44% using AI-driven job optimization. And when it comes to accuracy, AI-supported warehouses achieve an impressive 99.5% order accuracy rate. That’s a big deal, considering that mispicks cost companies an average of $390,000 annually. These operational improvements closely mirror the benefits AI brings to demand forecasting and stock replenishment.

Cutting Costs and Boosting Cash Flow

AI-powered automation also tackles labor-intensive tasks, like picking and sorting, with remarkable efficiency. Autonomous vehicles, for example, can reduce labor costs by 64% while increasing productivity by 33%. Consider a chemical manufacturer that used to rely on 200 manual forklift trips each week. After adopting the Cyngn DriveMod Tugger, which moves four pallets at once, they saw their efficiency multiply fourfold. Similarly, AI-powered drones scan inventory 25x faster than manual methods. One warehouse cut its inventory counting process from 90 days to just 2.5 days, all while maintaining a 99.9% accuracy rate.

Scalability for E-Commerce in the U.S.

Whether you’re managing a single warehouse in Texas or a network of facilities across the country, AI systems scale with ease. Take Walmart, for example. They’ve deployed millions of ambient IoT sensors across 4,600 stores and 40 distribution centers. These sensors automatically confirm receipts and monitor conditions like temperature and location – no manual scanning required. Unlike traditional systems that follow rigid rules, AI adapts on the fly. If an aisle is blocked, AMRs instantly reroute, keeping operations smooth even during high-pressure times like Black Friday or the holiday season.

Seamless Integration with Existing Systems

Modern AI tools are designed to work with your existing warehouse management systems (WMS), enterprise resource planning (ERP) software, and order management systems (OMS). AI doesn’t just pull data from these platforms – it also feeds optimized parameters back into them. This includes updates like new picking routes or adjusted reorder points. To get started, many businesses launch a pilot program in a controlled environment. This helps identify any integration gaps and builds team confidence before rolling out on a larger scale. By tracking metrics like order accuracy, fulfillment speed, and cost per order, you can measure the success of these systems and lay the groundwork for a more efficient inventory management strategy.

5. Anomaly Detection, Risk Management, and Stock Health Monitoring

AI plays a crucial role in catching and addressing anomalies before they turn into major problems. By analyzing massive datasets, AI can spot issues like sudden drops in sales, unexpected stock discrepancies, or supplier delays – things that human teams might overlook, which is why many are adopting Claude 3 AI for business to automate these complex checks. Machine learning algorithms flag these irregularities almost instantly, sending alerts when critical performance metrics are breached. This early detection system helps minimize financial risks and operational hiccups, complementing other AI-driven processes.

Impact on Inventory Accuracy and Efficiency

AI ensures real-time monitoring of stock levels and sales trends, creating a single, dependable source of truth. When inconsistencies pop up – like items marked as shipped but still sitting on the shelf – AI flags them for immediate review. This proactive approach reduces issues like overselling and misplaced inventory. For example, in 2025, Danone enhanced its demand forecasting for perishable goods, cutting forecast errors by 20% and improving overall accuracy to 92%.

Cutting Costs and Boosting Cash Flow

AI helps businesses identify slow-moving inventory before it becomes dead stock, unlocking cash flow. Automated systems can recover lost revenue by disputing shortage claims, achieving up to a 70% success rate. For perishable goods, AI connects to environmental sensors to monitor conditions like temperature and humidity, sending alerts if storage requirements aren’t met. In 2025, Shelf Engine’s AI-powered forecasting helped a grocery chain cut waste and labor costs, generating $40 million in additional profit in just one year. Companies leveraging AI for inventory optimization often see a 5–15% reduction in inventory levels and holding costs, along with a 10–20% improvement in service levels.

Scalability for U.S.-Based E-Commerce Operations

AI adapts seamlessly to manage anywhere from 10,000 to 10 million SKUs across multiple warehouses. As your product catalog expands, AI optimizes stock levels for each SKU and location. It also enables "what-if" scenario testing, letting you evaluate the effects of disruptions – like a port closure or a viral TikTok trend – before making inventory decisions. This kind of forward-thinking planning is especially useful during high-demand periods like Black Friday or the holiday season, when sales can surge unpredictably.

Seamless Integration with Existing Systems

AI integrates smoothly with ERP, WMS, and OMS systems, automatically updating optimization settings as needed. For example, if AI detects a supplier’s lead time increasing, it can adjust reorder points in your ERP system without requiring manual input. In June 2025, Walmart’s "FAST Unloader" AI system reduced unloading times by 30% and lowered stockout rates by 25%. To get started, consider piloting an AI project using 12–18 months of clean data in a high-impact area.

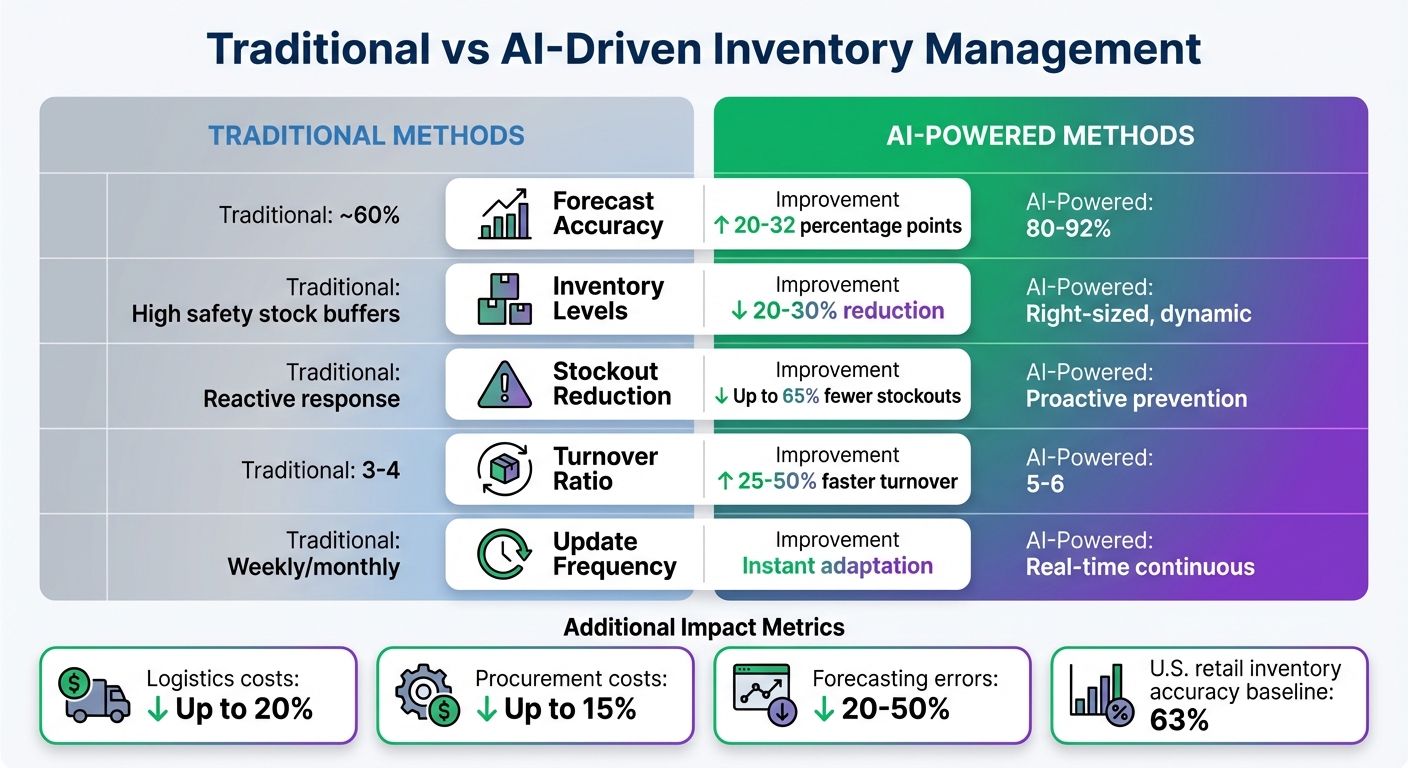

Comparison: Traditional vs. AI-Driven Inventory Management

Traditional vs AI-Driven Inventory Management: Key Performance Metrics Comparison

Looking at the differences between traditional and AI-powered inventory management, it’s clear that AI brings a whole new level of efficiency and precision.

Traditional inventory systems in the U.S. retail sector typically achieve around 63% accuracy, while AI-driven systems push that figure to 80% or more, with some implementations reaching an impressive 92% accuracy. This leap isn’t just about numbers – it has a direct impact on the bottom line. AI can slash forecasting errors by 20–50%, reduce inventory levels by 20–30%, and cut stockout rates by up to 65%.

The key difference lies in how decisions are made. Traditional methods rely on rigid rules and historical data, updated only weekly or monthly. AI, on the other hand, works in real time, continuously learning from live data and factoring in external elements like weather, social media trends, and competitor pricing. For instance, while traditional systems might overlook an unexpected weather event, AI can spot it and adjust inventory plans accordingly.

The financial benefits of AI are equally striking. Companies using traditional methods often see inventory turnover ratios of 3–4, while AI-driven systems can achieve 5–6. Logistics costs can drop by up to 20%, and procurement costs by up to 15% when AI is in the mix. A great example is More Retail Limited in India, which implemented Amazon Forecast in 2025. Their forecast accuracy jumped from 24% to 76%, in-stock rates improved from 80% to 90%, fresh produce waste dropped by 30%, and gross profit increased by 25%.

| Metric | Traditional Method | AI-Powered Method | Improvement |

|---|---|---|---|

| Forecast Accuracy | ~60% | 80%–92% | 20–32 percentage points |

| Inventory Levels | High safety stock buffers | Right-sized, dynamic | 20–30% reduction |

| Stockout Reduction | Reactive response | Proactive prevention | Up to 65% fewer stockouts |

| Turnover Ratio | 3–4 | 5–6 | 25–50% faster turnover |

| Update Frequency | Weekly/monthly | Real-time continuous | Instant adaptation |

These numbers make it clear: AI doesn’t just tweak inventory management – it revolutionizes it. Traditional methods are reactive, responding only after stock hits predefined reorder points. AI, by contrast, constantly adapts, adjusting safety stock based on real-time risks and supplier lead times. For example, a regional retailer managed to cut inventory costs by 40%, reduce stockouts by 25%, and lower overstocking by 30% within just six months of adopting AI.

Conclusion

AI is reshaping how e-commerce businesses manage inventory. Instead of scrambling to fix issues like stockouts or overstocking after they occur, companies can now anticipate and avoid these problems altogether. By moving away from outdated spreadsheets and guesswork to real-time data analysis, businesses reduce errors, lower costs, and enhance customer satisfaction.

The impact of AI on inventory management is hard to ignore. It improves forecasting accuracy, streamlines inventory processes, and ensures better product availability. By Q1 2025, 98% of companies have already incorporated AI into their supply chains to optimize inventory. Ignoring this shift could mean falling behind competitors who are already reaping its benefits.

To get started, focus on solving one pressing issue – whether it’s frequent stockouts of top-selling products or dealing with surplus inventory. Building a strong data foundation is essential for training AI models effectively. Success comes from blending AI’s predictive capabilities with human insights, especially when launching new products or navigating unexpected market changes. This combination ensures a smoother transition to AI-driven inventory management.

For businesses seeking a comprehensive AI toolkit, Fello AI (https://claude3.pro) offers access to cutting-edge tools like Claude, GPT-5.1, and Gemini on Mac, iPhone, and iPad. Whether you’re tackling demand forecasting, inventory planning, or exploring AI’s potential in your operations, having multiple AI models at your disposal can simplify the process and help tailor solutions to your needs.

With generative AI projected to contribute $240 billion to $390 billion annually to the retail sector, the question isn’t whether to adopt AI – it’s how quickly you can integrate it. Embrace AI now to optimize your inventory and stay competitive in a fast-evolving market.

FAQs

How does AI enhance demand forecasting for e-commerce inventory?

AI transforms demand forecasting in e-commerce by combining historical sales data with real-time trends, seasonal fluctuations, promotional activities, and external factors like market changes. Machine learning plays a key role here, continuously adjusting to shifts in consumer behavior. The result? Sharper predictions that help businesses strike the right inventory balance – avoiding both overstocking and stockouts.

This approach doesn’t just streamline inventory management. It also cuts costs, reduces waste, and ensures customers can find what they’re looking for exactly when they need it. By tapping into AI, e-commerce businesses can adapt quickly and meet consumer demand in today’s ever-changing marketplace.

How does automated replenishment benefit inventory management in e-commerce?

Automated replenishment simplifies inventory management by keeping stock levels in check and cutting down on waste. It ensures shelves are always stocked, reducing the chances of missed sales or overstocked items sitting idle.

This method also sharpens accuracy, balances inventory levels, and contributes to healthier profit margins. By automating the process, businesses can save money, work more efficiently, and offer a smoother shopping experience to their customers.

How does AI improve real-time inventory tracking in e-commerce?

AI combines data from various sources – such as sales orders, warehouse updates, supplier schedules, and even external factors like weather or social trends – into one constantly updated view of your inventory. This means no more relying on outdated spreadsheets or delayed reports. Instead, you get accurate, real-time insights across all your locations.

With near real-time analysis, AI can quickly identify issues like low stock or sudden demand surges. It can even take proactive steps, such as automatically replenishing stock or redistributing inventory, to address problems before they impact your customers. This improved visibility helps prevent stockouts, reduces excess inventory, and supports smarter decision-making, ensuring your e-commerce operations stay flexible and efficient.